|

14/06/2022

|

Tech - Products

Why choosing the right electromechanical systems provider is crucial: Delta Line wheel drives for AGVs and AMRs |

|

Developing a new product or optimizing an existing product no longer means just providing a version that performs better than the last one. To be successful, designers and manufacturers must now deliver improved performance, increased efficiency, and smaller footprint. By working with a partner who has expertise in both electromechanical components and systems, you can ensure your system is optimized to meet – and exceed – these expectations.

One of the biggest challenges when designing an electromechanical system is to meet the oftentimes competing objectives of maximizing performance and minimizing footprint. And on top of these requirements, more and more types of devices are being designed to operate on battery power, so efficiency also becomes increasingly important.

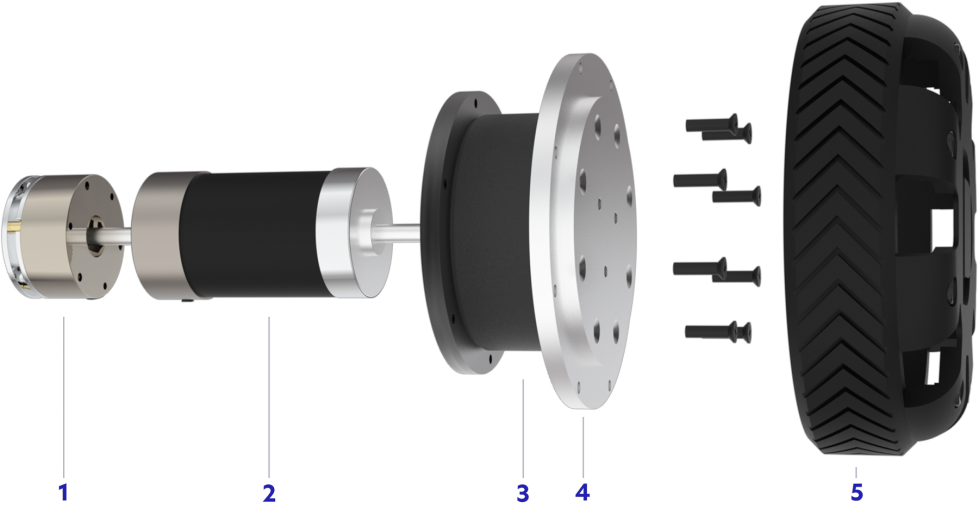

But these design goals – high performance, high efficiency, and small footprint – don’t have to be mutually exclusive. Manufacturers of all kinds of components – from motors and actuators to sensors and electronics – have been developing products to meet these specific requirements for several years. The key is to work with a partner who has experience not only manufacturing individual components, but also integrating these components into complete electromechanical systems. Manufacturers who possess both the technology expertise and integration experience, such as Delta Line, can propose creative solutions that help you meet – and even exceed – your design and performance goals. Case Study: Wheel drives present unique challenges for electromechanical systems Take, for example, our wheel drives for AGVs (automated guided vehicles) and AMRs (autonomous mobile robots). Because wheel drives – sometimes referred to as wheel hub drives – are battery powered, they need to be as efficient as possible, not only for energy-saving purposes, but also because recharging an autonomous system takes valuable time and costs money. But at the same time, the wheels that drive AGVs and AMRs must be able to operate at high speeds and produce sufficient torque to carry the specified payload while meeting the required acceleration and move profile. And when an electromechanical system is truly integrated, or embedded, into the final product, these challenges become even more complex. Constraints such as footprint and battery size become more rigid, and there are fewer design options that satisfy these requirements. But these challenges were no problem for Delta Line. In addition to our expertise in manufacturing a wide range of individual components – such as BLDC motors, gearboxes, and drives – our team also has decades of experience developing complete electromechanical systems that maximize performance and efficiency. And we partner with our customers to integrate these systems directly into their end devices. When we developed the new wheel hub drives for AGVs and AMRs, we used this expertise to design a solution that not only met the technical requirements, but that did so with a level of design flexibility not previously available in the market. For example, one of the performance requirements for AGV and AMR wheel hub drives is that they must be able to withstand significant radial loads. To address this application challenge, we based our design on one of our standard planetary gearboxes, but with the addition of two large ball bearings on the external ring to provide the radial load capacity necessary for these demanding applications. And although wheel drive designs often use gearmotors, we chose the planetary gearbox for better efficiency and longer life. In fact, throughout the design of the wheel drives, we focused on using high-efficiency components and innovative designs to ensure the overall system efficiency remained as high as possible. This gives the end user the longest possible battery life, so the time and cost of recharging is minimized. Our wheel drive solutions also have a feature that many integrated systems lack – the ability to customize them to match the requirements of each application. We understand that these wheel drives will be integrated into all types of AGVs and AMRs, and with our flexible design, they can be easily optimized to provide the best solution for each customer and application. For example, we can provide custom tires to suit the rolling surface and environment. In fact, our wheel drives can be used in many other applications besides AGVs and AMRs, such as sliding lift doors, conveyors, rotary tables, and large pumps.  1. Optional brake 2. Motor 3. Gearbox 4. Mounting flange 5. Tire (customer specified) Choose a partner who can optimize performance and cost Our engineers recognize that there’s no point in maximizing performance and efficiency if, in the end, the solution is too expensive for the customer or the application, so they always keep in mind the cost of the system as well as the total cost of ownership for the user. This, together with the dual benefits of Swiss design and Chinese manufacturing, allows us to produce innovative products – and even customized systems – with an excellent price-to-performance ratio. As the development of our new wheel drive shows, because we control each aspect of the motion – from the mechanics to the electronics – we can come up with innovative solutions and system designs. To discuss your application and learn more about our products and capabilities, give us a call or contact us. Whether it’s a motor, a subassembly, or a completely integrated system, with our insight and collaboration, you’ll get more than just a product that works, you’ll get a system that’s optimized to meet your requirements – even if those requirements appear at first to be mutually exclusive. |

Latest

News

News